Project SpindleHot, created by Dr. Malcolm Ross and his “HotRock” Research Consortium team at the Bureau of Economic Geology (BEG), plans to tap into a source of heat energy previously thought to be inaccessible via traditional geothermal means: salt domes.

“Salt has some interesting characteristics beyond flavour enhancement. For example, did you know that salt is mobile over human time scales, and it behaves like toothpaste being squeezed upwards into myriads of shapes by heavy overlying sediments,” says Dr. Ross.

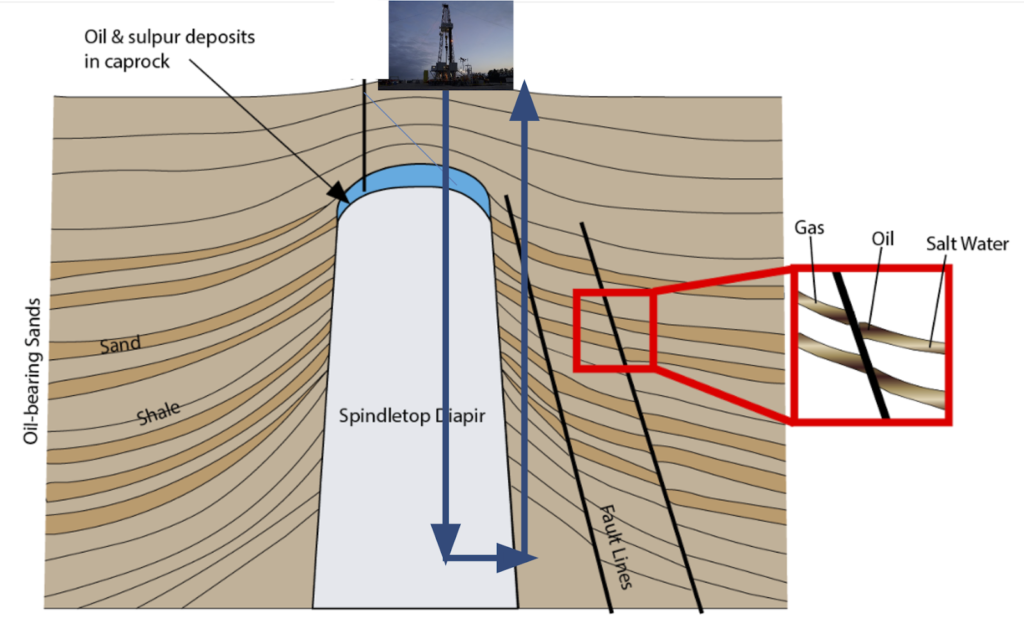

Salt is less dense than sedimentary rock, has no permeability, and is 5-7 times more thermally conductive. According to Dr. Ross, salt diapirs could act as chimneys, taking heat from as deep as 10 kilometres in the earth and channeling it closer to the surface.

The purpose of Project SpindleHot is to evaluate the geothermal potential of these salt domes, and further research is set to commence at places like the Spindletop salt diapir, home of the very first oil well in Texas, which produces oil from the diapir caprock.

Salt bodies themselves have been historically unattractive for oil and gas sectors (while the sediments and caprock associated with the salt bodies have been of great interest), as well as traditional geothermal, as there is no feasible means to utilize it for energy – the lack of permeability (and the self-healing behavior of the mobile salt) means there is no way to produce or move fluids through the rock. However, Dr. Ross proposes that an isolated and conduction-based closed-loop geothermal system may hold great potential and could possibly be demonstrated to be the only technology to harness energy from salt domes.

“If we were to make it a closed-loop system, we could access the heat via conduction and, thus, would not need to rely on permeability. In other words, until the recent advent of closed-loop geothermal, this approach would not have been possible,” says Dr. Ross.

Given the lack of permeability, high thermal conductivity, and substantial risks and opportunities of drilling into salt diapirs, Dr. Ross suggests that further research is needed to construct an appropriate solution for a closed-loop system within salt domes. One possibility would be to encase the wellbores with steel; alternatively, with an open-hole multilateral completion design, a hypersaline working fluid could be used to reduce the erosion of the multilateral wall due to the dissolution of the surrounding salt.

Furthermore, suppose a closed-loop system was drilled into a salt dome. In that case, Dr. Ross explains that it’s possible for the salt’s high thermal conductivity surrounding the return wellbore will “suck away” heat from the returning hot working fluid. To mitigate this, he proposes two solutions. One solution is to insulate the return wellbore. The second is to situate the return flow wellbore in the less conductive surrounding rock (Figure 1).

Project SpindleHot’s next steps are to drill a well (hopefully at Spindetop) to evaluate temperature structure and salt movement velocity to understand if it is possible, and if so, how to construct equipment that can withstand these geological conditions. Then, continue the possibility for collaboration with Eavor-Loop™ technology. The “HotRock” team is looking for sponsors for its geothermal research consortium, under which Project Spindlehot will execute.