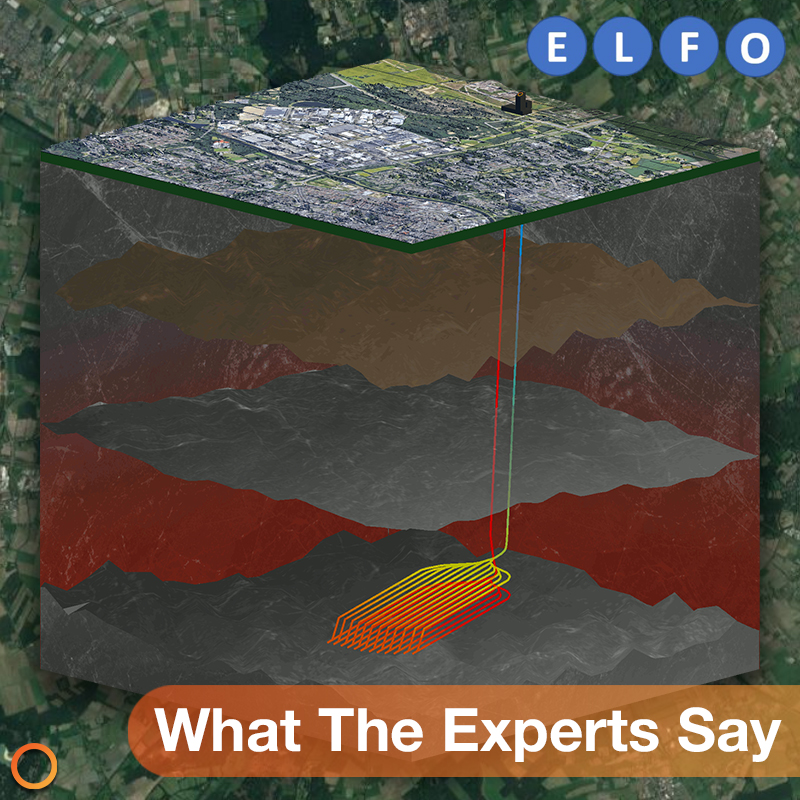

Eavor-Loop™ Feasibility for Tilburg (Amer network) and Outlook for application in the Netherlands

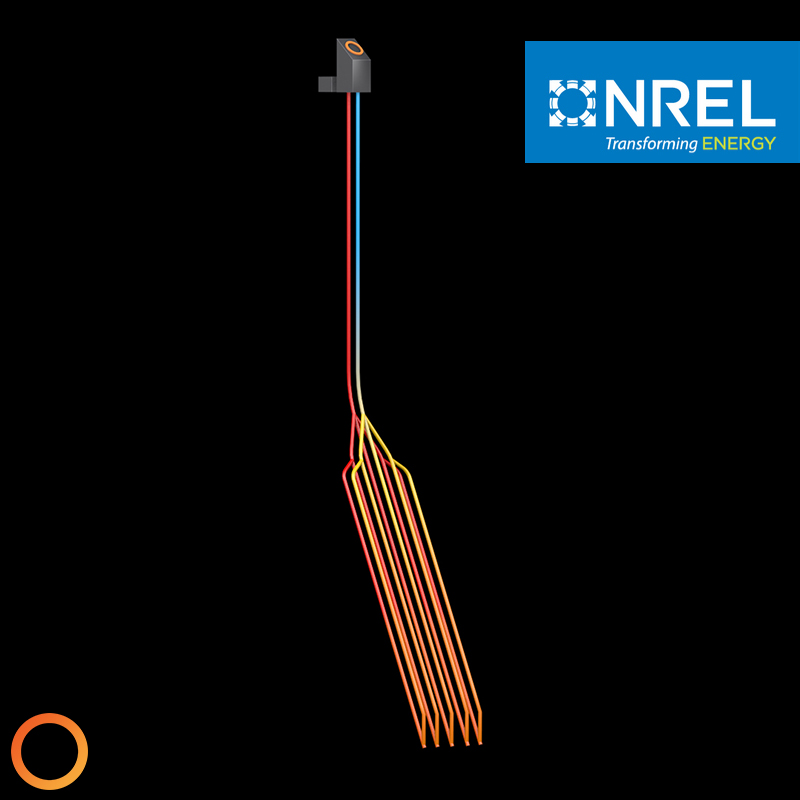

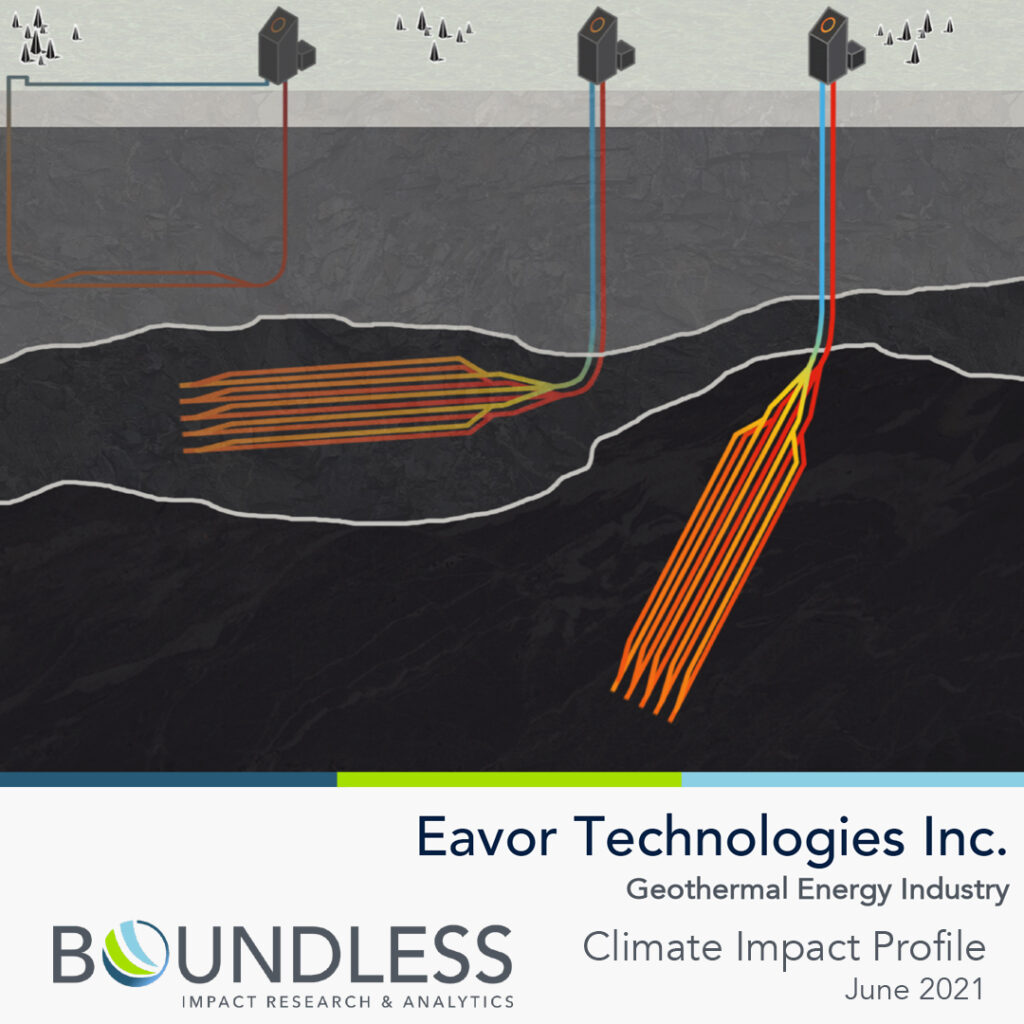

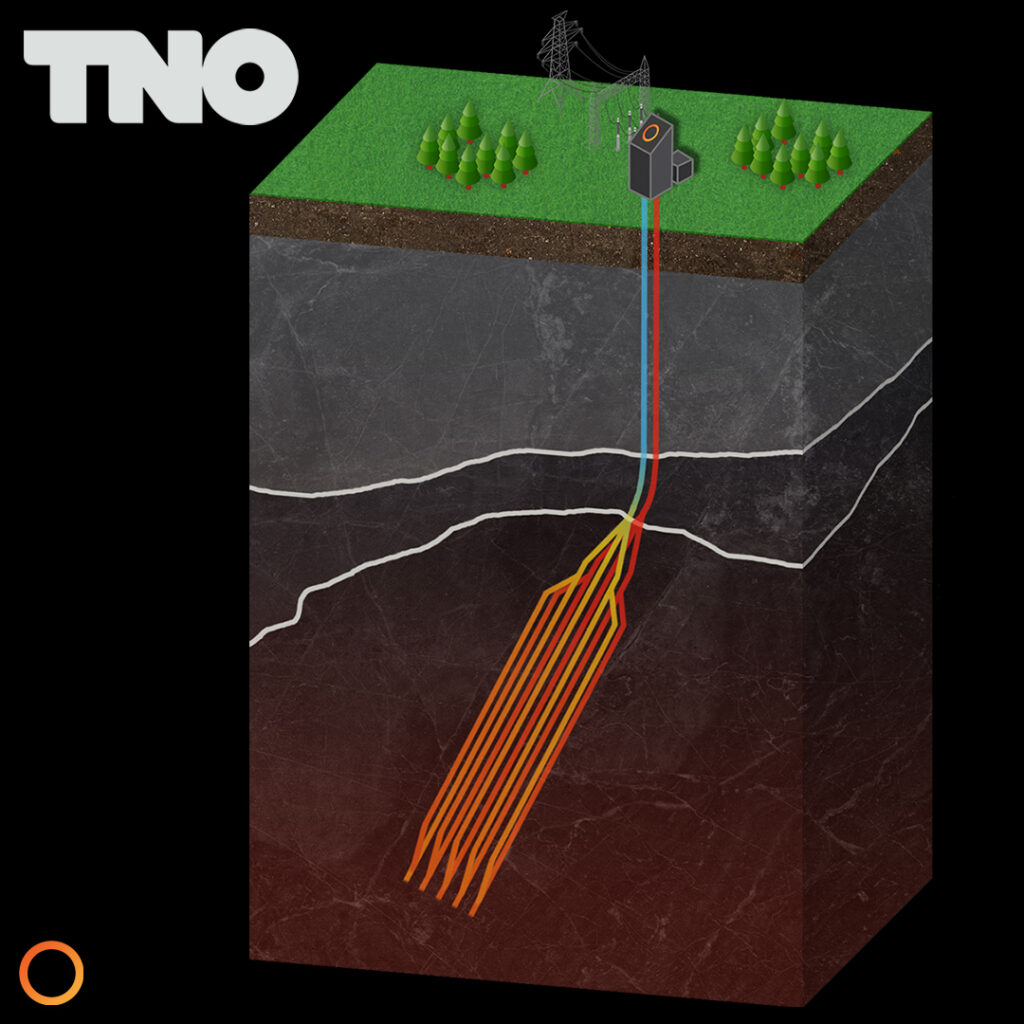

The energy generation and consumption in the Netherlands is slowly but steadily shifting away from fossil fuels towards renewable energy sources, such as offshore wind, and solar, thereby reducing greenhouse gas emissions. In order to improve renewable energy security and affordability, other sources of renewable energy, like geothermal energy, need to become part of the energy mix in the near future. At present, the majority of geothermal wells in The Netherlands are shallow wells, but deeper wells with high power output will be required to make a larger contribution to the overall energy supply. In this light, the ELFO project assessed the feasibility and economic viability of a deep well system: the Eavor Loop, consisting of 12 multi-laterals. The consortium of TNO (independent research institution), Eavor (geothermal energy company), Huisman Geo BV (drilling equipment & research) and EnNatuurlijk (operator of district heating) evaluated the suitability of this technology as primary heat source for city heating networks in the Tilburg area and for possible wider adaption in the Netherlands.