Technology

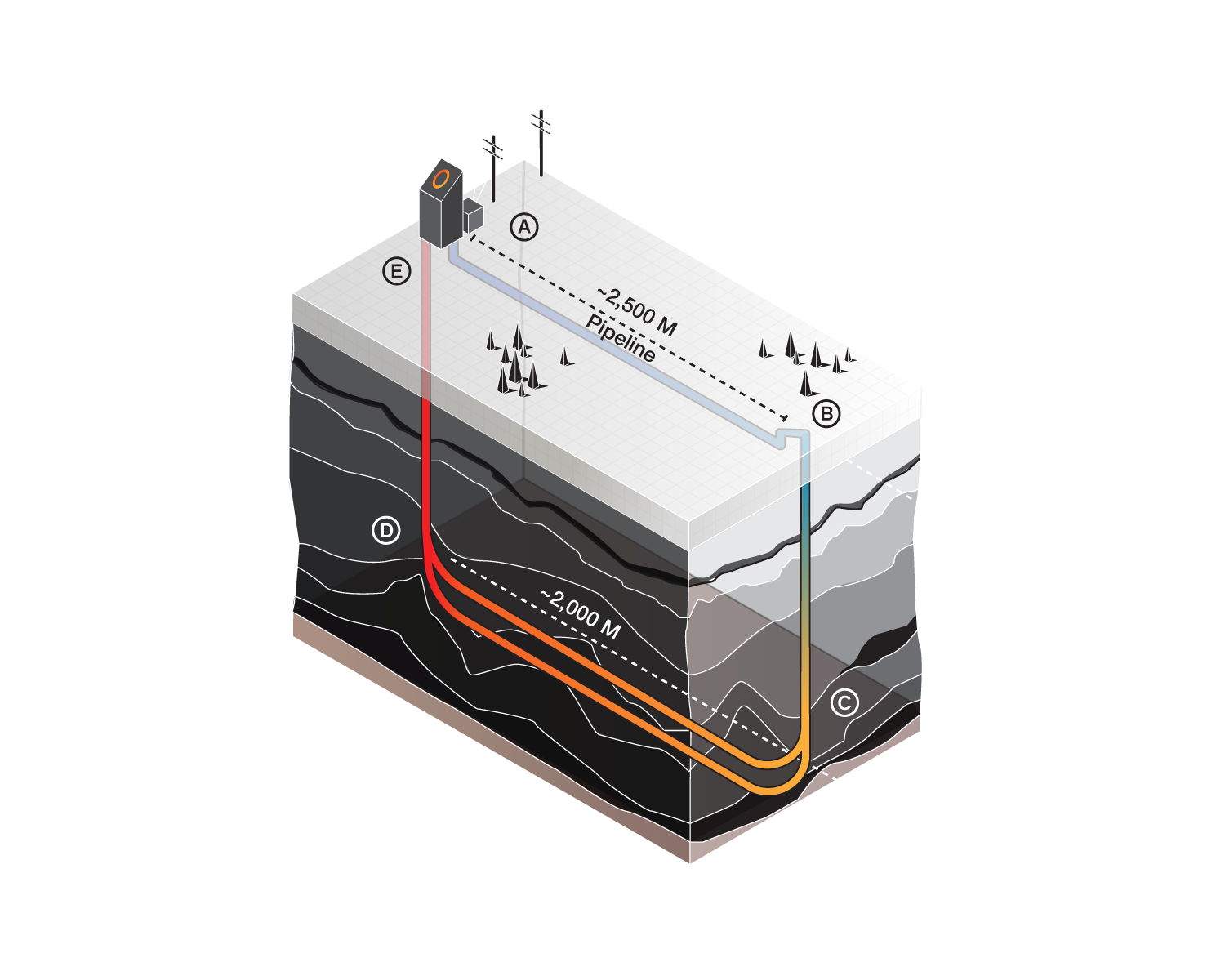

An Eavor-Loop™ is the connection of two vertical wells with many horizontal multilateral wellbores creating a closed sealed radiator-like system. Eavor’s proprietary working fluid is not from a reservoir, it is selected and added at surface, then circulated to harvest heat from deep in the Earth to be used to generate electricity or in commercial heating/cooling applications.

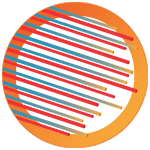

Rock-Pipe™

The profiled multilateral sections are completely separated from the rock and each other using Eavor’s protective Rock-Pipe™ completion technology. Working fluids are permanently isolated and contained within the system.

Dispatchability

An Eavor-Loop ™ can slow down and even pause its flow, to allow the fluid to stay within the hot rock for a longer period of time and pick up additional charge. The Eavor-Loop ™ can then ramp up and dispatch that higher temperature fluid, on-demand when the sun goes down or the wind stops blowing…

Insulated Drill Pipe

Insulated Drill Pipe (IDP) is key to our hotter/deeper project plans. We have developed & built IDP technology that converts conventional pipe into a means to control bottom-hole temperatures. This serves two purposes; to actively cool off-the-shelf drilling technologies to reach depths and temperatures previously seen as impossible, and to increase drilling speed.

Modular Organic Rankine Cycle

The ORC (Organic Rankine Cycle) turbogenerator uses medium-to-high-temperature thermal oil to preheat and vaporize a suitable organic working fluid in the evaporator. The organic fluid vapor rotates the turbine, which is directly coupled to the electric generator, resulting in clean, reliable electric power.

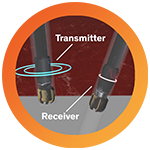

Magnetic Ranging

Magnetic Ranging Technology, a borrowing from the energy services sector, provides us the ability to accurately intersect our wells at a target depth. The process is efficient and safe, using magnetic ranging signals from one BHA to the other.

Multilateral Junctions & Whipstock

During the drilling process, in the vertical section of the Eavor-Loop ™, we create junctions where the multilaterals will be drilled from. The direction of the drill bit is adjusted using a whipstock which is inserted ahead of the drill bit to guide the bit through a specific junction.

Spread Section

A series of lateral legs stemming out from the vertical and cased well section after the 90° turn. Precise multilateral drilling is designed to specific subsurface profiles to maximize efficiency.

Intersection

Magnetic Ranging Technology, a borrowing from the energy services sector, provides the basis to make these, at depth intersections consistent, efficient and safe.

Thermosiphon Effect

The closed-loop system in an Eavor-Loop™ allows the fluid to circulate without a parasitic load, providing global scalability.

Multilateral / Rock-Pipe™

The profiled multilateral sections are completely separated from the rock and each other using Eavor’s protective Rock-Pipe™ completion technology. Working fluids are permanently isolated and contained within the system.

Benign Footprint

The world’s most benign environmental impact & surface footprint. Eavor can fit in a backyard, repurpose inactive well sites or decommissioned industrial/commercial facilities. The facility has no emissions of any kind during operations.

Resilience & Sustainability

The Eavor-Loop™ system requires no connection to the outside world and operates without fuel and is completely emission-free. The fully-independent system can be placed in a bunker or buried below surface to be made resilient to natural disasters.

How Rock-Pipe™ Works - With Vlad & Mo

Geothermal Will Change Our World... ForEavor

We are transforming the power industry

Eavor’s technology consists of several Patent Pending innovations. The Eavor-Loop is a closed system within which a proprietary working fluid is contained and circulated. The working fluid is not fluid from a reservoir flowing into our wells, it is a fluid added to the closed-loop Eavor-Loop™ to create an efficient radiator, much like a vehicle radiator circulates fluid in a closed loop to remove heat from a gasoline engine.

Eavor-Loop™ harvests heat from deep in the earth to be used for commercial heating applications (ex: greenhouses or district heating) or to be used to generate electricity using conventional heat to power engines. Eavor-Loop™ is an industrial scale geothermal system that mitigates many of the issues with traditional geothermal systems, which rely upon using wells to produce brine from a subsurface aquifer.

The closed-loop is the key difference between Eavor-Loop™ and all traditional industrial-scale geothermal systems. Eavor-Loop™ is a buried-pipe system, which acts as a radiator or heat exchanger. It consists of connecting two vertical wells several kilometres deep with many horizontal multilateral wellbores several kilometres long. As these wellbores are sealed, a benign, environmentally friendly, working fluid is added to the closed loop as a circulating fluid. This working fluid is contained within the system and isolated from the earth in the Eavor-Loop™. The wellbores act as pipes, not wells producing fluid from the earth.

The working fluid naturally circulates without requiring an external pump due to the thermosiphon effect of a hot fluid rising in the outlet well and a cool fluid falling in the inlet well. The working fluid contained in this closed loop pipe system brings thermal energy to the surface where it is harvested for use in a commercial direct heat application or converted to electricity with a power generation module (heat engine). Unlike heat pumps (or “geo-exchange”), which convert electricity to heat using very shallow wells, Eavor-Loop generates industrial scale electricity or produces enough heat for the equivalent of 16,000 homes with a single installation.

How Eavor Works

– The ability to drill and intersect a multilateral Eavor-Loop™ with 2 laterals

– The ability to simultaneously drill and seal the wellbores, creating a closed-loop that is isolated from the surrounding formation and will neither leak fluid out of the Eavor-Loop™ nor allow formation fluids to ingress into the Eavor-Loop™.

– Prove the thermodynamic performance of the Eavor-Loop™ – that the subsurface heat transfer and thermosiphon effect match expectations.

Economic, clean, reliable power. – Energy never stops.

Eavor-Loop™ can be implemented almost anywhere at scale. Our sites can exist close to urban centres or in remote locations where getting electrical power is historically challenging.

Eavor-Lite™ Demonstration Facility

The Derek Riddell Eavor-Lite™ Demonstration Facility is a full-scale prototype of the Eavor technology suite. The facility site is located near Rocky Mountain House, Alberta. Drilling and construction began in August of 2019. Eavor-Lite™ consists of two vertical wells, joined by two multilateral legs at 2.4km depth, connected by a pipeline at surface. The rationale for this design, which is not intended to be commercially viable, is to build a facility that proves and demonstrates all the critical elements of Eavor’s technologies at the lowest cost. This demonstration is designed to achieve the most efficient path to acceptance and commercialization of the technology by facility developers and commercial financiers.

The Eavor-Lite™ Demonstration is designed to achieve the following three technical objectives:

- Drill and intersect a multi-lateral Eavor-LoopTM with 2 lateral wellbores from each vertical wellbore

- Intersect wellbores/mechanically confirm intersect

- Seal lateral openhole wellbores while drilling

- Pressure test

- Maintain circulation rate with negligible leak rate

- Maintain low solids production

- Validate thermodynamic performance and demonstrate thermosiphon effect

- Match or exceed thermodynamic model performance

- Demonstrate thermosiphon control and operation

- Achieve >90% uptime